semi active implant

Reliable Stability. Advanced Osseointegration. Designed for Success.

Pivot Implants presents the Active Implant with 5° Morse taper connection, a high-performance dental implant engineered for immediate and long-term clinical success. Built with Grade 4 titanium, this implant ensures superior strength, excellent biocompatibility, and a precise conical connection that minimizes micro-movements and bacterial infiltration.

Key Features:

Sand blasted, Large grit, Acid-etched implant surface, (SLA) is a type of surface treatment that creates surface roughness with the goal of enhancing osseointegration through greater Bone to Implant Contact (BIC).

The SLA process increases the rate at which osseointegration occurs by using a combination of Grit & Acid etching to give the surface increased roughness on multiple levels.

This allows osteblasts to proliferate and adhere to the implant surface. Through osseointegration, SLA can help provide increased stability of the implant which will ultimately lengthen its longevity.

We also do the extra treatment for cell adhesion, which reduces the amount of treatment time required while also increasing the treatment Predictability.

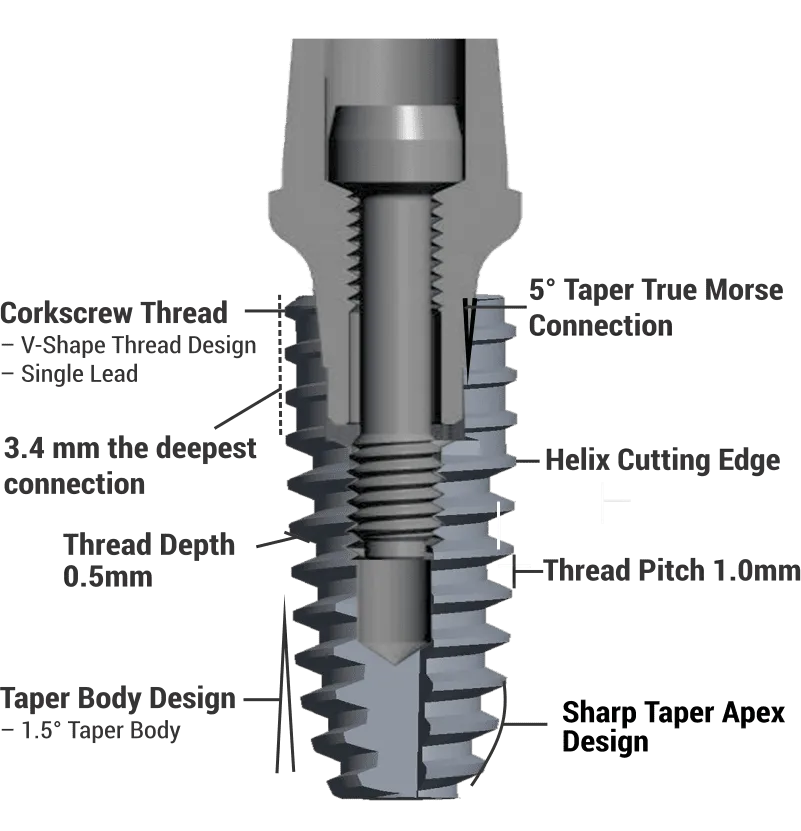

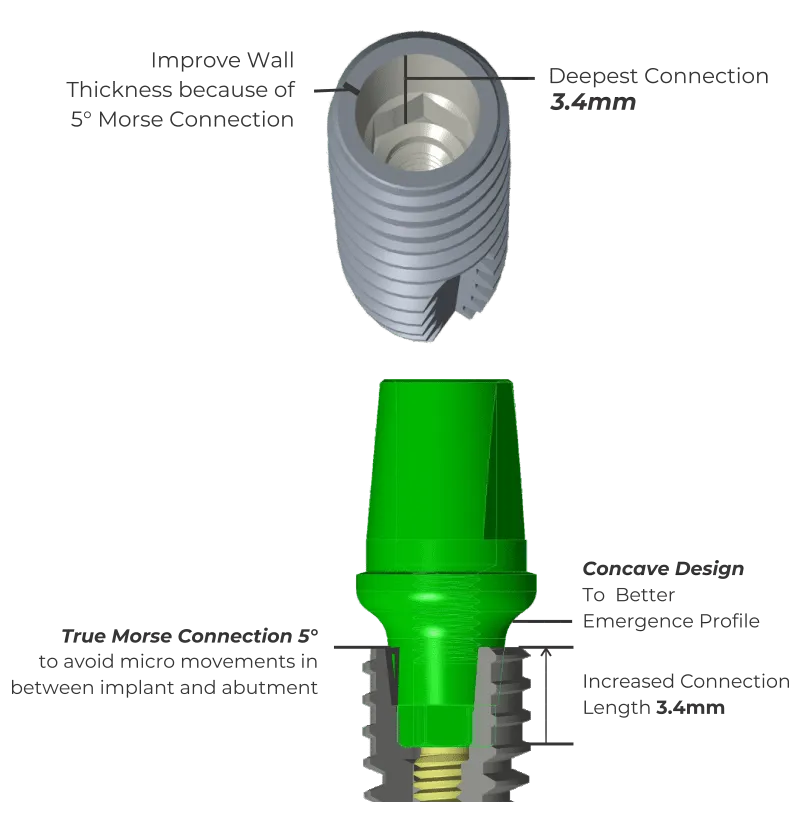

Pinnacle Morse Design

5° Semi Active Pinnacle Internal Connection

Ultra-Clean Surface Technology

Clean Surfaces

Superior Raw Material

Packaged To Stay Clean

Dental Implants are delivered in uniquely designed protective packaging. In this superior quality packaging of medical grade polyethylene.

ability.

- Grade 4 Titanium for Implant

- Grade 5 for Abutments and Screws etc.

Packaged For Convenience

- Delivered sterile and ready for use. (Gamma Rays)

- Compact for easy of storage in dental clinic.

- Effective performance for ease of handling and use.

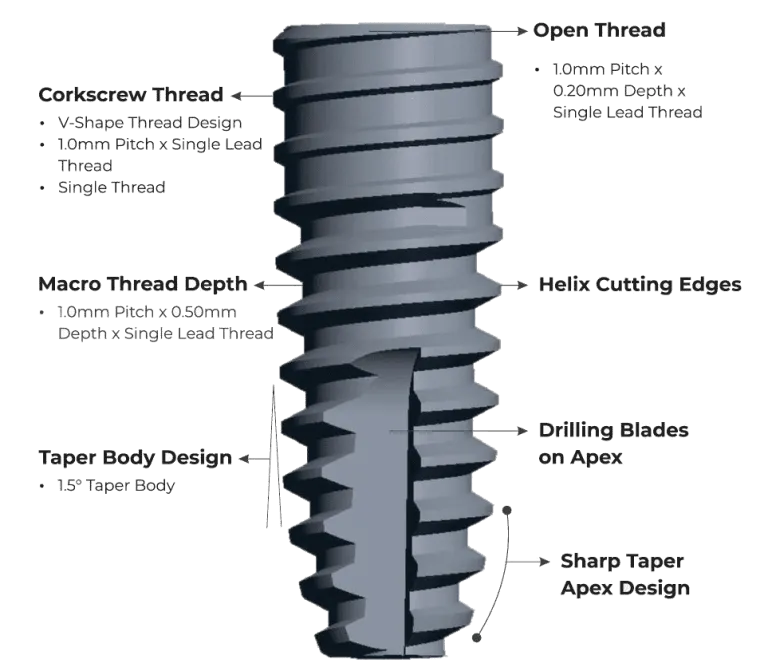

Implant Design

The Evolution of Implant Design

A new generation implant combining a traditional passive approach with a modern aggressive approach was designed by Pivot to generate optimized bone properties. Our unique design and world class quality make us the leading dental implant manufacturer in India.

- Tapered progressive thread for enhanced initial stability.

- Accurate osteotomy that meets the implant design

- Carefully tested drilling protocol that enables insertion torque of 30-50 NCM for abutment screw we need torque 25 NCM due to our small angle of matching of abutments with implant